What`s New

-

NIF Newsletter: Sept-Oct 2025-English

NIF Newsletter: Sept-Oct 2025-English -

List of shortlisted candidates against Adv-01-2025

List of shortlisted candidates against Adv-01-2025 -

NIF Newsletter: July-August 2025-English

NIF Newsletter: July-August 2025-English - Rajbhasha Patal Activities

- Inspiring journey of P.G. George

- Padma Shri Hariman Sharma- The apple man of India !

- The entries for 15th National Biennial Campaign for Green Grassroots unaided Technological Innovations, Ideas & Outstanding Traditional Knowledge are open till 31st March 2027

- Video Glimpses of NIF's Silver Jubilee Celebration

- 25 Years of Innovation- Celebrating Grassroots creativity

- NIF-India Documentary

- Celebrating 25 years of Innovation - SILVER JUBILEE CELEBRATION

- विज्ञापन सं. 01-2025 के अंतर्गत चयनित अभ्यर्थियों की सूची

- रानप्र न्यूज़लेटर : सितम्बर–अक्टूबर 2025 (अंग्रेज़ी)

- NIF Newsletter: July-August 2025-Hindi

Messages

Updates

Podcast

About Us

The National Innovation Foundation (NIF) - India

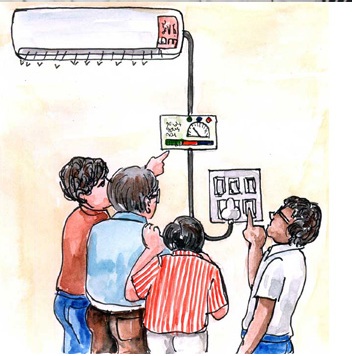

is India's national initiative to strengthen the grassroots technological innovations and outstanding traditional knowledge. Its mission is to help India become a creative and knowledge-based society by expanding policy and institutional space for grassroots technological innovators.

NIF scouts, supports and spawns' grassroots innovations developed by individuals and local communities in any technological field, helping in human survival without any help from formal sector. It also tries to ensure that such innovations diffuse widely through commercial and/or non-commercial channels, generating material or non-material incentives for them and others involved in the value chain... Read more

Departments

Grassroots innovators displayed their technologies at the @nifindia stall in the DST Pavilion during #IISF2025, Panchkula. Dr. V. Narayanan @isro & Shri Manohar Lal Khattar visited, alongside scientists, entrepreneurs, farmers, and 500+ students who engaged with the innovations. pic.twitter.com/Zh7VKbOlOI

— NIF - India (@nifindia) December 11, 2025

NIF–India’s Bhubaneswar Camp Office visited Gaya & Nawada (Bihar) to verify & document plant-based, herbal, veterinary, and engineering practices, securing PICs. A meeting at Kowakhol with ~40 farmers & innovators further strengthened community-led innovation efforts.@IndiaDST pic.twitter.com/wBZNjF0Bry

— NIF - India (@nifindia) December 8, 2025

VKA _Episode 124 Dr. R K Ravikumar