Vermi compost pellet making machine

Genesis

Vermin-compost is used as organic fertilizer and there are very few machines available in rural areas to manufacture compost in the easy-to-use pellet form. He chose to work on developing his vermin-com post machine spurred by Lokendra Singh of his village. Singh needed such a machine for his fields. Learning about Nitin?s innovative abilities, he explained his need to Nitin and asked him to develop the device. Nitin came up with this machine in a very short time and Singh used the machine for a couple of years. During this time, a few technical problems were also identified. Nitin has rectified the technical snags in design and is planning to make the next version of the product.

Innovation

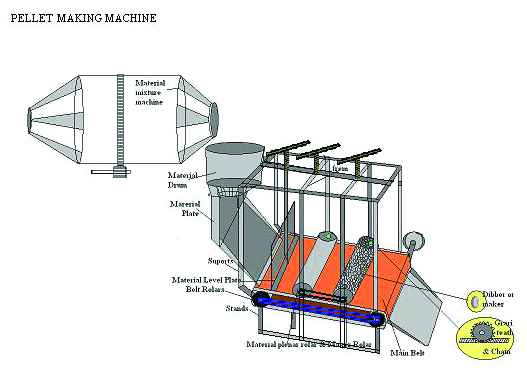

The current design is manually operated, and consists of a hopper, flat moving belt, a die to form pellets and power transmission system. A single person can operate the machine. The principle used involves mixing the vermi-compost with suitable binder (molasses), putting the mixture in the hopper, carrying the compost using the conveyor belt on a flat bed in the form of a sheet and passing through pellet making die to generate a stream of pellets. The pellets produced need less space to store and can be spread uniformly to the fields. In pellet form the release of the nutrients to the plants is slow and for a longer period.Having made the manual machine work, Nitin wants to develop a fully automatic version. This automatic machine will consist of a hopper, a binder-mixing unit, a spreading unit, conveyor, and a pellet making die, an electric motor and power transmission system. While the use of conveyor and die system to make pellets is known in chemical and pharmaceutical industries, the deployment of this concept to create "vermin-compost pellets" is novel in application.

We now feel as if a scientist has been born in our family

I am getting an idea

Background

Nitin (21 years) is a dedicated innovator par excellence. Challenged by a farmer to make a pellet-making machine, he designed this machine within a few months. It effectively makes pellets of vermi-compost that is to be spread in the field. He is presently pursuing his graduation in arts. He has also opened a computer shop ?Nitya InfoTech? where he offers computer training, Internet facilities as well as hardware sales and repair. He studied at Hapur and now stays at Meerut with his maternal uncle. His father, mother and a younger brother, who is presently studying in class 11th live in Hapur. His father used to practice medicine earlier but now has settled as an agriculturist. Being a curious child, he used to take things apart to examine them and put them back in new ways. He spent all his money on his projects rather than on clothes, foods, friends or the movies His unbridled curiosity was a source of trouble for his parents; he failed his 10th class though he did well in science subjects. The fact that he lived away from home in his uncle?s house and came home occasionally softened his parents? stance and relented. Commenting on his achievements, his mother now proudly proclaims, "ab lagta hai hamare ghar mein vaigyanik paida hua hai"1 His brother, Robin recalls that whenever Nitin got any idea, he used to say, "Mere dimaag mein idea aa raha hai"2 and used to run to his room and lock himself inside. He did not come out of it until he had done some substantial work on his idea. A few years ago, he met Deepak Sharma, District Coordinator of Centre for Science and Technology (DST). Sharma was impressed by his skills and arranged for a room and computer for Nitin in the NCC office at the NAS Degree College, Meerut so that he could work on his innovations in peace. Burning the midnight oil, he spent two whole years in that room in 2004-2005, creating a wide repertoire of innovations. Among them is the fire sensor activated switch, which sounds an alarm signal to alert people. It can also be used to operate the carbon-dioxide cylinder valve or water tank valve to quench the fire. This switch can be installed anywhere, and consists of a thermometer, a bell and an automatic gas valve. Apart from developing other things that would make life easier for the common people, Nitin plans to enhance the efficiency of engines so that they optimally utilize the depleting non-renewable resources. He has had his share of fame but he says he wants to keep away from the all the distractions and lime-light and keep on innovating. Though he has his own shop and business, at times, he feels tied down by it and wants to break free and only concentrate on innovating.

Awarded by NIF

Patent filled No:402/DEL/2007

NA

NA